Back

With Stafsjö’s valves Firefly protects valuable installations worldwide

When it comes to industrial fire protection systems, reliability is essential. On constant standby during long periods, the system should be able to respond immediately and extinguish possible ignition sources to prevent fires and dust explosions. In the Firefly solution, Stafsjö’s valves have an important duty.

For more than 30 years ago, Firefly decided to use Stafsjö’s valves in their fire protection systems. Firefly develops its high safety solutions in Hammarby Sjöstad and exports them throughout the world. Almost 80 % of its output is sold outside Sweden.

– Demand is high and growing all the time. For our customers, fire protection is extremely important. It must not go wrong. Therefore, we must also be able to rely on our subcontractors. In our system, the valve itself is a critical component, says Kristoffer Tannerfeldt, Risk Manager at Firefly.

Firefly’s industrial business area covers customers within the food industry who deal with cereals, cocoa and sugar, but also board, diaper and pellet manufacturers, all of whom handle raw materials that represent high ignition hazards. Major investments and other financial assets are at stake. And the fact that people can be injured and even killed as a result of industrial fires and dust explosions makes the need for reliable spark and industrial fire protection systems even greater.

Within the system developed by Firefly, there are detectors that identifies dangerous particles (ignition sources) in the process flow. When a detector recognizes any kind of deviation, the control unit sends a signal to the isolation valve, which closes before the dangerous particles have passed through. Extinguish media can be water, but CO2 gas is also commonly used to reduce oxygen level quickly to prevent fires from starting.

– In a fraction of a second, the flow must be blocked and the process closed completely. Therefore, our systems must be on constant standby, inactive for long periods, and ready to be activated, explains Kristoffer.

– We have more than 30 years’ experience of Stafsjö’s valves. They are robust, reliable, and deliver performance when required. It is a reliable product that provides the quality we and our customers value. With a closed knife gate, we can prevent fires and dust explosions and thereby enhance levels of fire safety at our customers.

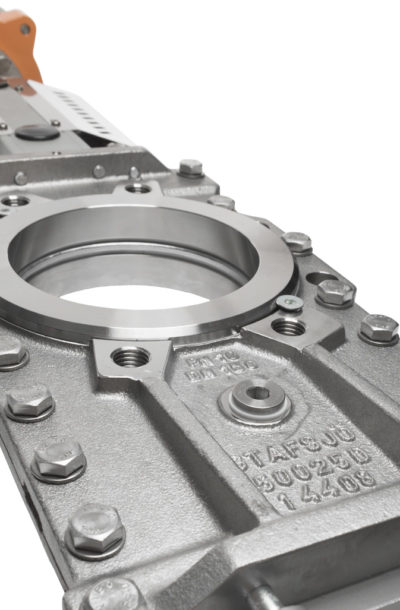

Firefly uses Stafsjö’s HG isolation valve with through-going gate for reliable shut-off performance independent of pressure direction. Its ability to cut through static media columns also serve its purpose well. Superior flow characteristics enable it to act as a part of the pipe system without affecting the process flow. Stainless steel metal seats extend the service life and offers low friction to achieve ultra-fast isolation time. Sometimes the valve is also supported by a pressure tank to speed up the shut-off time.

With a strong workforce of 80 dedicated people, Firefly has made a name for itself over the years. Clients are now made up by users in Europe, North America, Asia and South America, and increase in numbers every year.