Knife gate valve

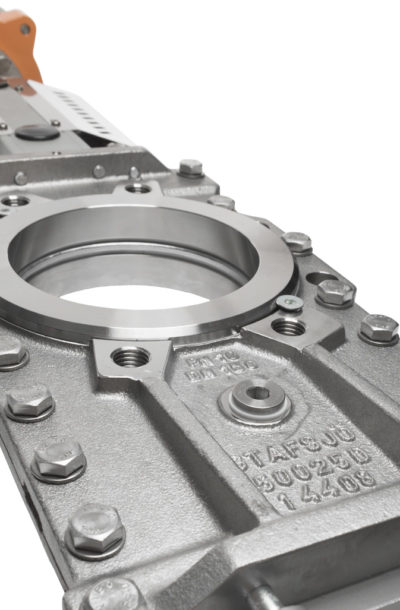

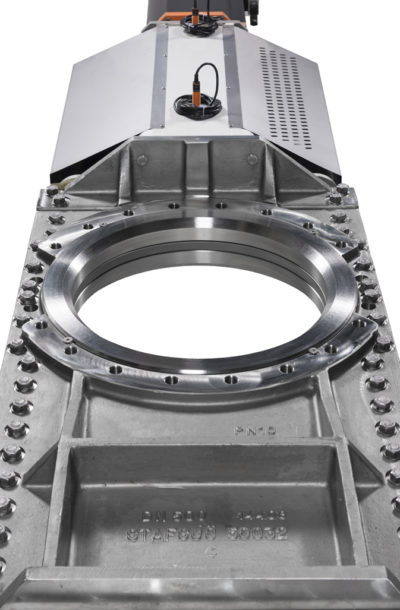

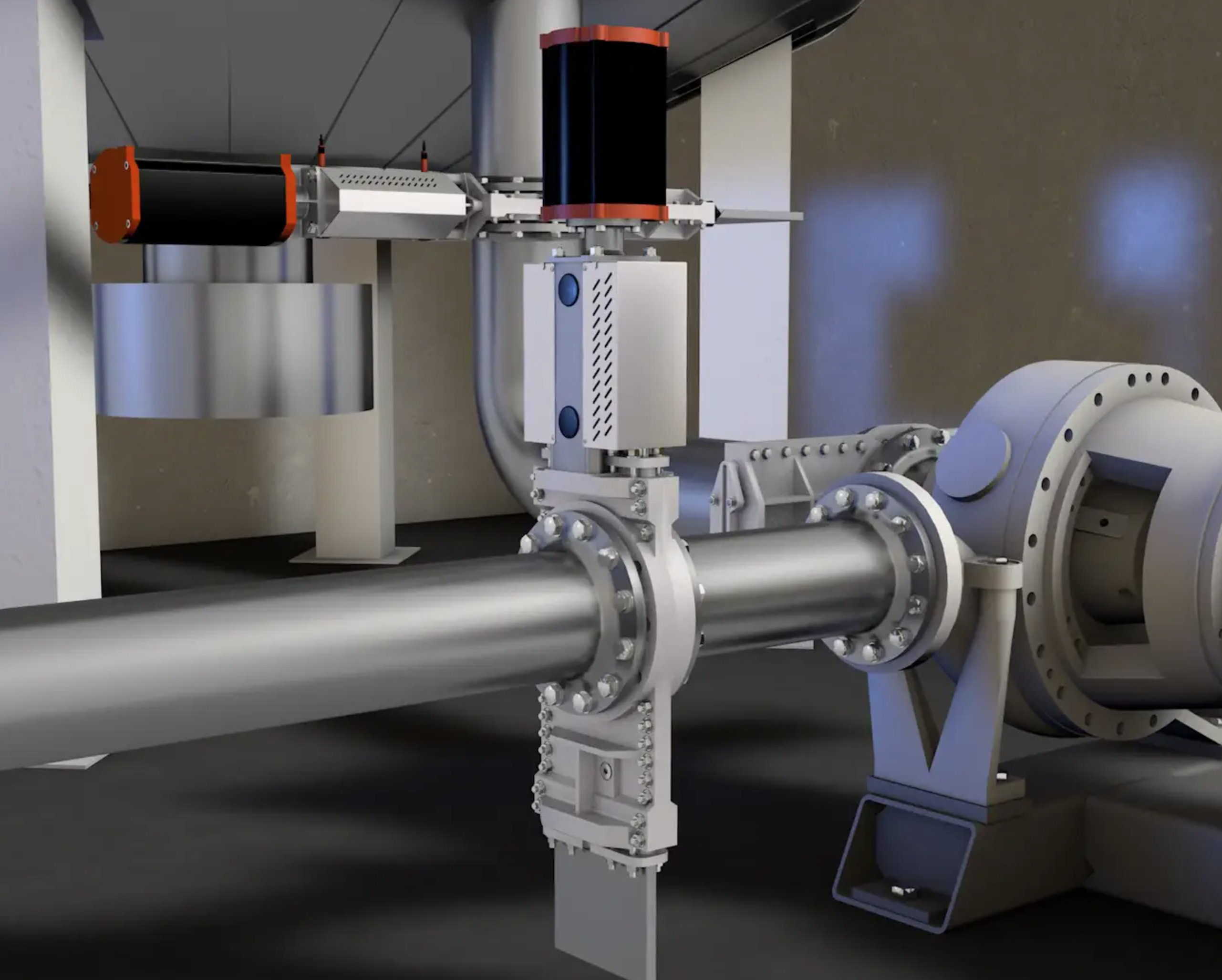

HL

A compact through-going knife gate valve for low pressure applications.

Available size range:

DN 400 - DN 800 (16” - 32”).

Product data sheet:

Discover more

About HL

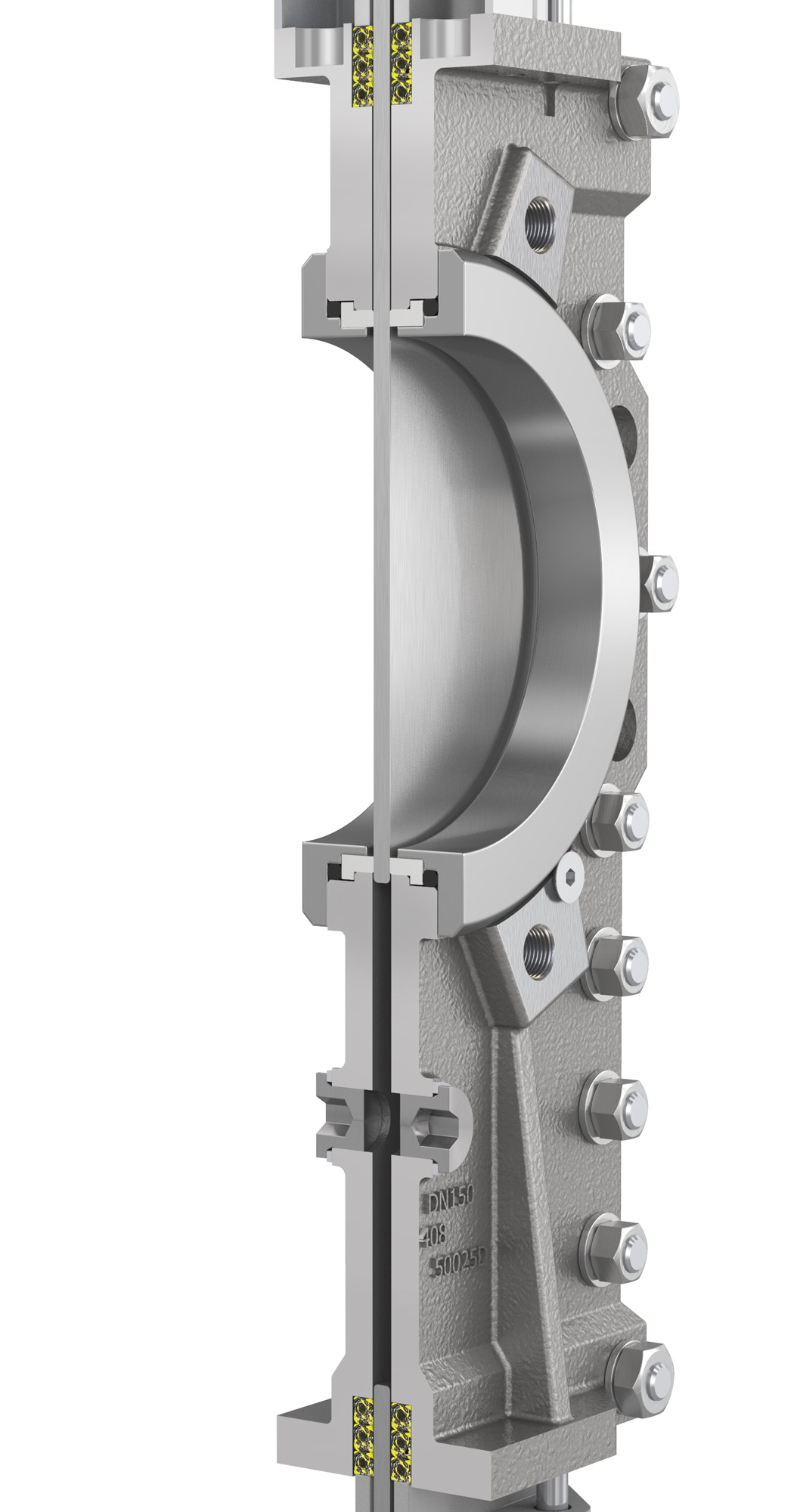

Stafsjö’s HL is a through-going knife gate valve with superior flow characteristics, offering reliable bi-directional zero leakage shut-off on highly concentrated media and static media columns.

The HL knife gate valve can operate on different media such as pulp stock up to 18 % concentrations, liqour, ash and granulate. It is modular designed and can easily be customized in materials, with actuators and related automation accessories to different process conditions. The valve has a two piece precision machined valve body in stainless steel with a high strength top works that provide an essential and precise gate alignment.

The HL valve is one out of five of Stafsjö’s through-going knife gate valves. The HG represent standard. HP is a high pressure version of HG and the HPT is a high pressure version entirely made in Titanium. Finally the HX is an extreme high pressure version.

Specifications

Shut-off technique

Bi-directional

Through-going

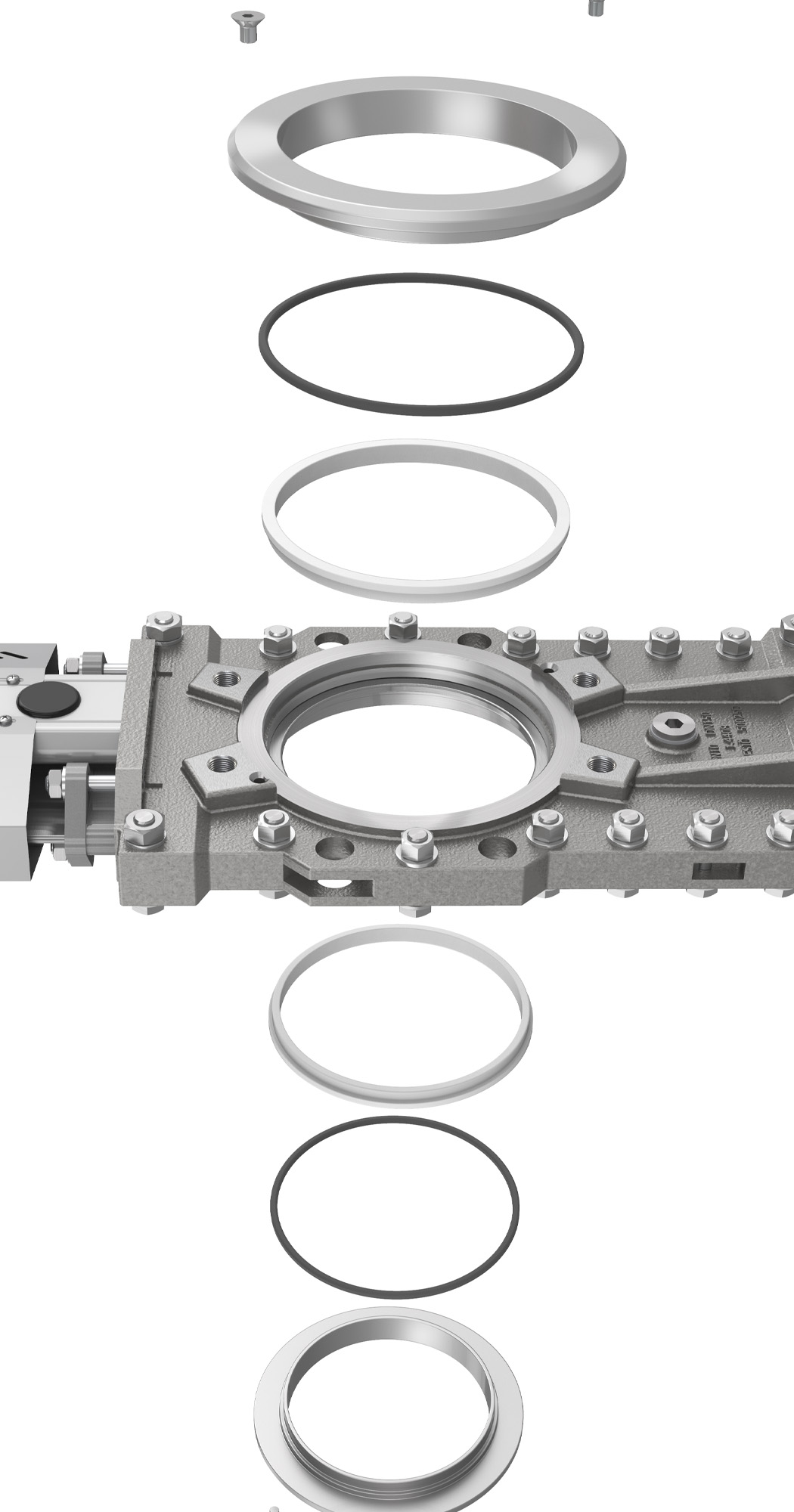

Valve seat material

PTFE

Connection type

Wafer/Semi lugged

Valve body material

Stainless steel

Industries

Chemical

Power

Pulp and Paper

Product features

Full bore with outstanding flow characteristics

Reliable through-going and bi-directional zero leakage shut-off

The retainer ring system extend service life

Downloads

- Title Format Size Restriction

-

Knife gate valve HL

PDF 938 KB

- Title Format Size Restriction

-

Double acting pneumatic cylinder SC

PDF 1 MB -

Manual actuators

PDF 2 MB -

Hydraulic cylinder

PDF 2 MB -

Electric motor AUMA

PDF 91 KB -

Electric motor LINAK

PDF 1 MB

- Title Format Size Restriction

-

Knife gate valve specification guide

PDF 5 MB

- Title Format Size Restriction

-

Installation and service instruction

PDF 4 MB -

Maintenance instruction HG, HL, HP, HPT and HX

PDF 655 KB

- Title Format Size Restriction

-

3D STP HL DN400 DN500 EC PN10

ZIP 3 MB