Knife gate valve

XV

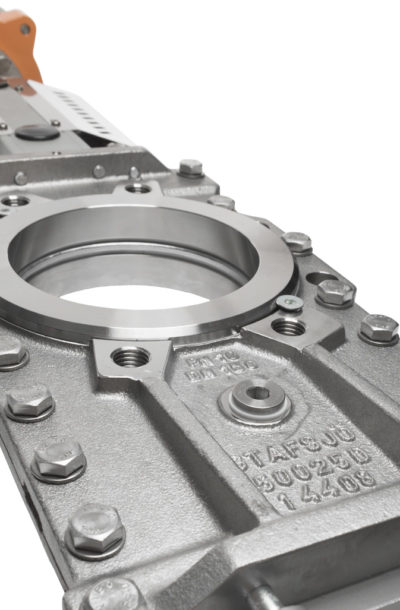

Bi-directional chemical resistant knife gate valve in stainless steel

Available size range:

DN 65 - DN 1000 (2.5" - 40")

Product data sheet:

Discover more

About XV

The XV knife gate valve offers excellent flow characteristics and bi-directional zero leakage shut-off. It is a compact chemical resistant valve suitable for fluids such as pulp stock, biomass and sludge.

The XV valve is modular designed and can easily be equipped with manual as well as automatic actuators and related automation accessories. It is as standard supplied with PTFE seats and stainless steel wetted parts. The valve body is available in a fully lugged version up to DN 600 and a semi lugged version all the way up to up to DN 1000. There is also a dead end service version available in sizes DN 80 – DN 200.

Download the product data sheet for additional technical information.

Specifications

Shut-off technique

Bi-directional

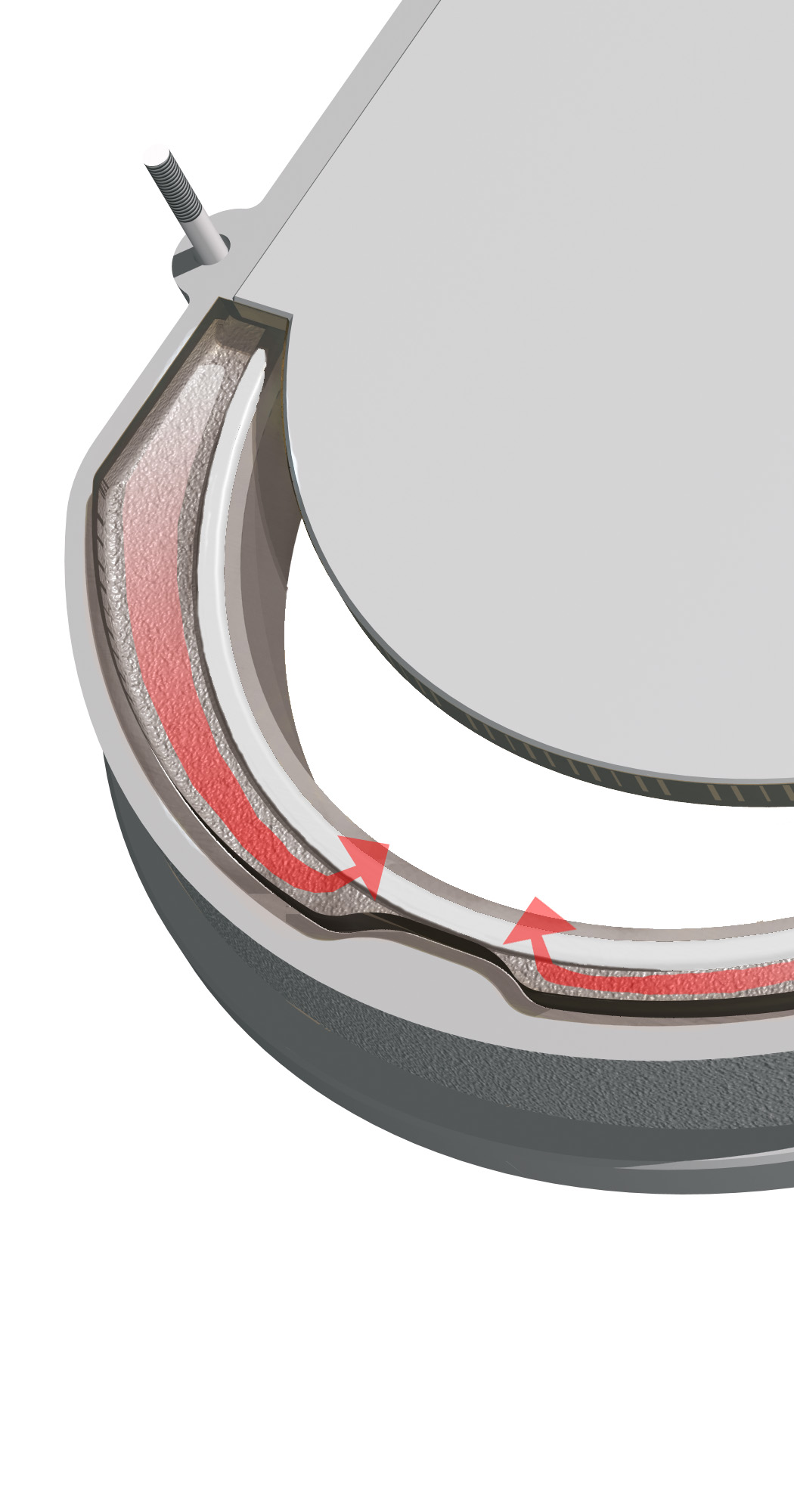

Valve seat material

PTFE

Connection type

Fully lugged

Wafer/Semi lugged

Valve body material

Stainless steel

Industries

Biomass

Chemical

Pulp and Paper

Water treatment

Product features

Full bore with excellent flow characteristics

Bi-directional zero leakage shut-off

Self-cleaning function

Downloads

- Title Format Size Restriction

-

Knife gate valve XV

PDF 1 MB

- Title Format Size Restriction

-

Manual actuators

PDF 2 MB -

Double acting pneumatic cylinder SC

PDF 1 MB -

Electric motor AUMA

PDF 91 KB -

Electric motor LINAK

PDF 1 MB -

Hydraulic cylinder

PDF 2 MB -

Stafsjö standard accessories

PDF 4 MB

- Title Format Size Restriction

-

Knife gate valve specification guide

PDF 5 MB

- Title Format Size Restriction

-

Installation and service instruction

PDF 4 MB -

Maintenance instruction XV

PDF 458 KB

- Title Format Size Restriction

-

3D XV 80 200 HW

ZIP 2 MB -

3D XV 80 300 EC

ZIP 4 MB -

3D XV 350 800 EC

ZIP 5 MB