Durable valves in a tough environment

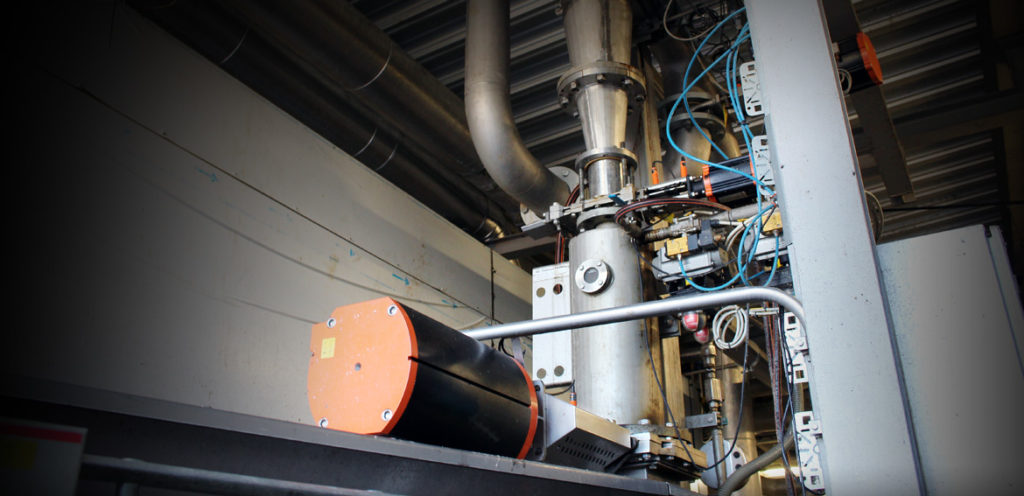

Presenting a tougher environment than that of many other processes, with low pH values and abrasive media, the processing of food, slaughterhouse and kitchen waste at Linköping’s biogas plant generates two highly demanded products – biogas and bio-fertilizer. We are talking about the achievement of a sustainable society in practice.

If it’s going to work, the process equipment must be capable to withstand tough strains, says Håkan Widerström, Maintenance Co-ordinator at Tekniska verken in Linköping, one of Sweden’s leading producers of biogas with its own in-house development department that willingly shares its experiences:

– The anaerobic digestion process tear heavily on the process equipment. It literally eats valves and pumps. One could say our environment is similar to a combination of pulp production and mining and its mineral processing. It is therefore important that we work with the right components from start.

Valves must close properly and remain tightly sealed. Even a micro leak can have devastating consequences. In instances where reverse flow occurs or the wrong material finds its way into the process, you have to terminate it and start all over again – with a severe production disturbance and non delivery as a consequence.

Håkan Widerström strongly believes you can count on a knife gate valve from Stafsjö to fulfil its duty.

– It’s designed and developed to meet challenging conditions, and he rest assured the flow is blocked when the valve is closed. Thereby the system also becomes easier to monitor and manage. Working with the right equipment not only minimizes maintenance work, it also provides a sense of security. We can focus on other aspects and quality assure the process and production chain, says Håkan.

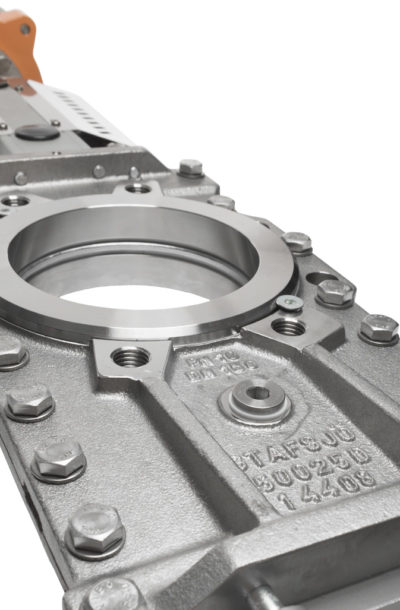

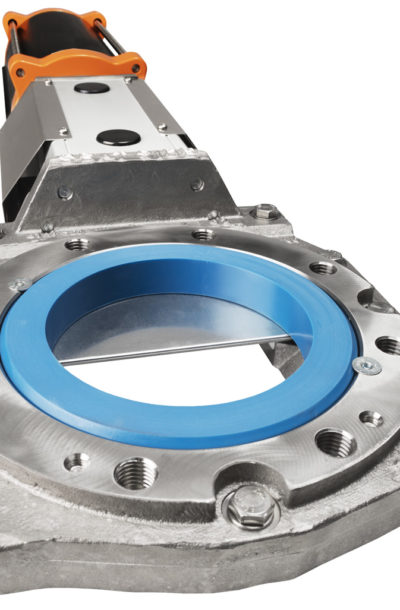

Tekniska verken mostly uses Stafsjö’s stainless steel MV valve that efficiently manages food waste with its cutting knife-like shut-off. The MV is also available in a nodular iron version for more pH neutral processes. The stainless steel XV valve is used where there is a need to ensure full tightness regardless of pressure direction.

A factor that determines the quality is the sorting of the household waste. Glass shards, bottle caps and eggshells are often included but add nothing positive. When the waste is placed in tanks this complicates the digestion process resulting in extensive maintenance as an outcome. With the help of a high density cleaner, which is also widely used in pulp and paper mills to clean the pulp, waste is separated from the biomass by a vortex and high density particles are collected in a reject chamber where the HG serves as the inlet valve and the robust RKO as the outlet valve.

The demand for biogas is high. Many municipalities and transport companies in Sweden are required to operate fossil free. Today, sustainability is a crucial criterion when an entrepreneur’s services are procured. This means biogas is relevant and timely right. On the one hand, household waste is disposed of, and on the other, digested to become fuel and organic fertilizer material for agriculture.

– From a sustainability perspective, it also feels right to use components that will last over time. We should not be part of the ’throw-away society’ without thinking about a cycle and conducting a life cycle analysis of the materials and resources we use, says Håkan.

Tekniska Verken in Linköping is a technology leader within its field and hold a competence that is widely demanded. Its strength also lies in the fact that they managed to prove to the market that the business can be run on a commercial basis.

Further information

Please feel free to contact Stafsjö on sales@stafsjo.se or on +46 11 39 31 00 for additional information on knife gate valves for the biogas industry.