Knife gate valve

RKO

This is the optimal valve solution for junc traps and high density cleaners

Available size range:

DN 100 - DN 600 (4” - 24”)

Product data sheet:

Discover more

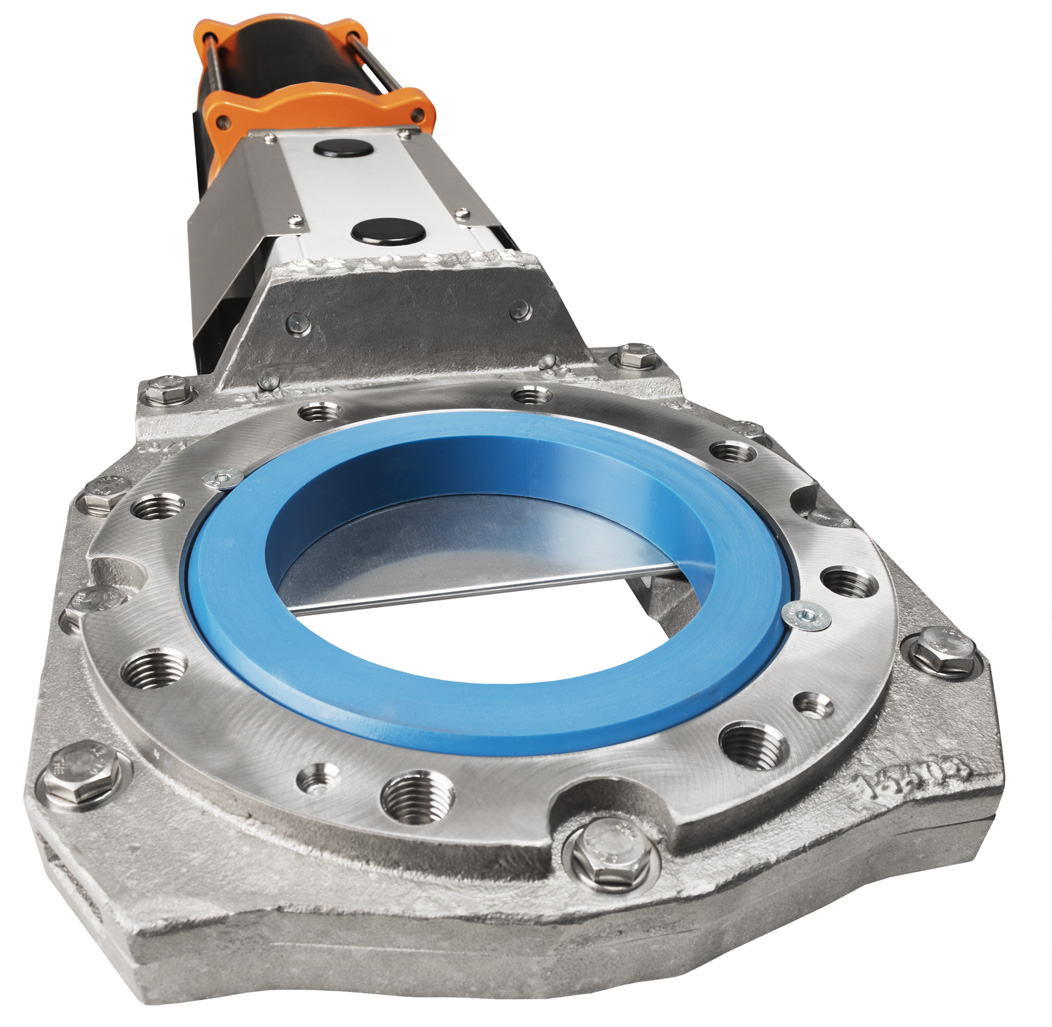

About RKO

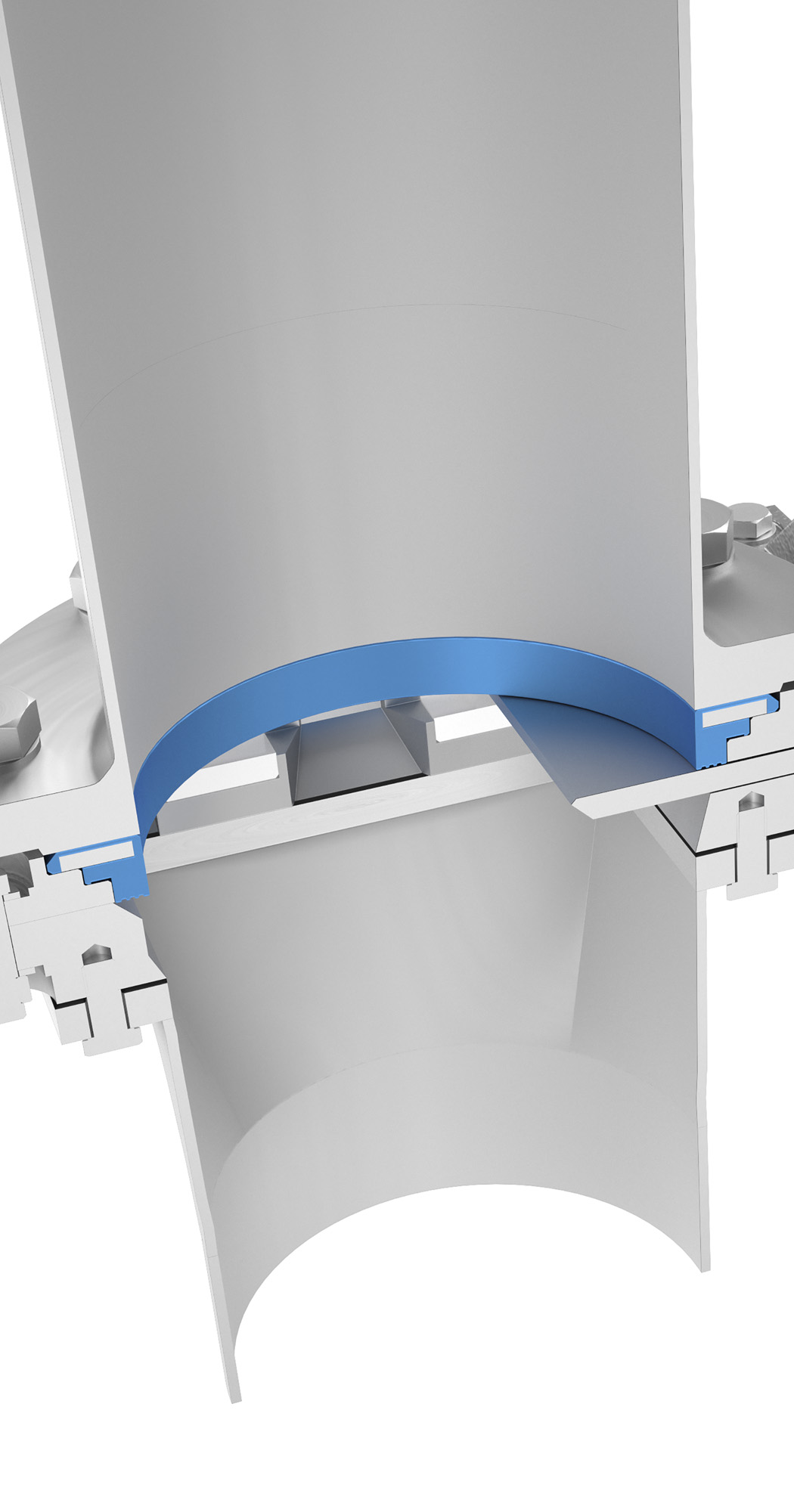

This is the optimal valve solution for junc traps and high density cleaners separating abrasive materials such as sand, stones, staples, glass and other type of rejects from the process media.

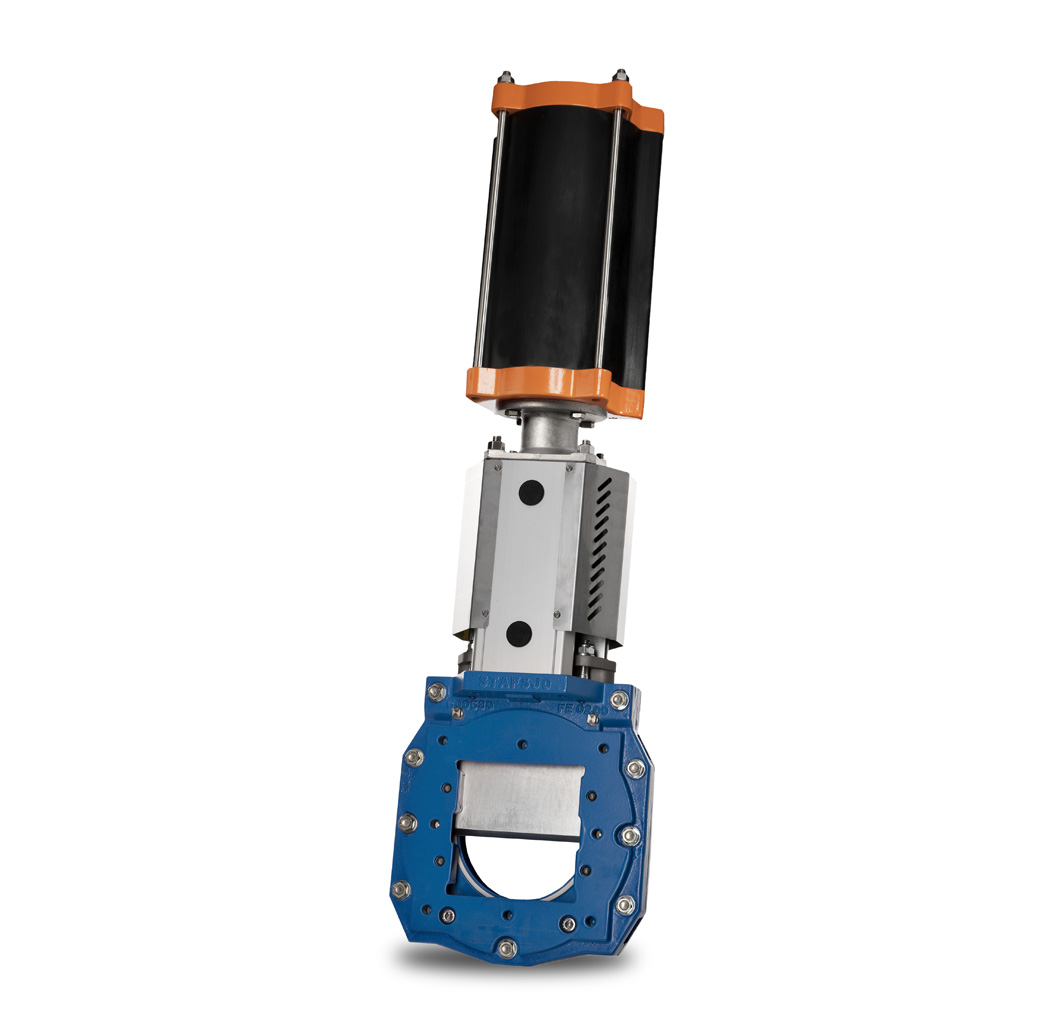

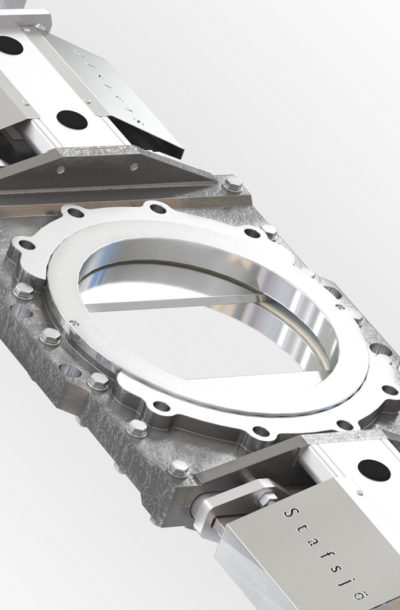

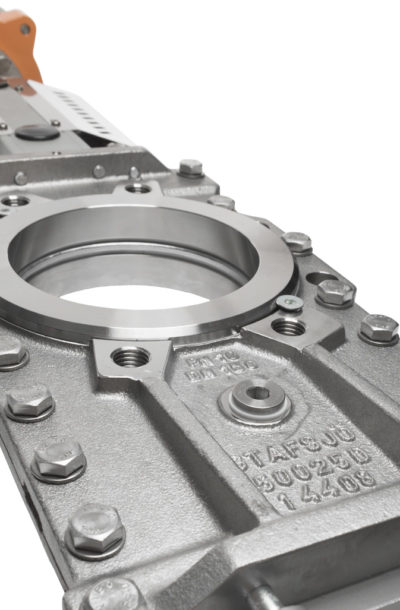

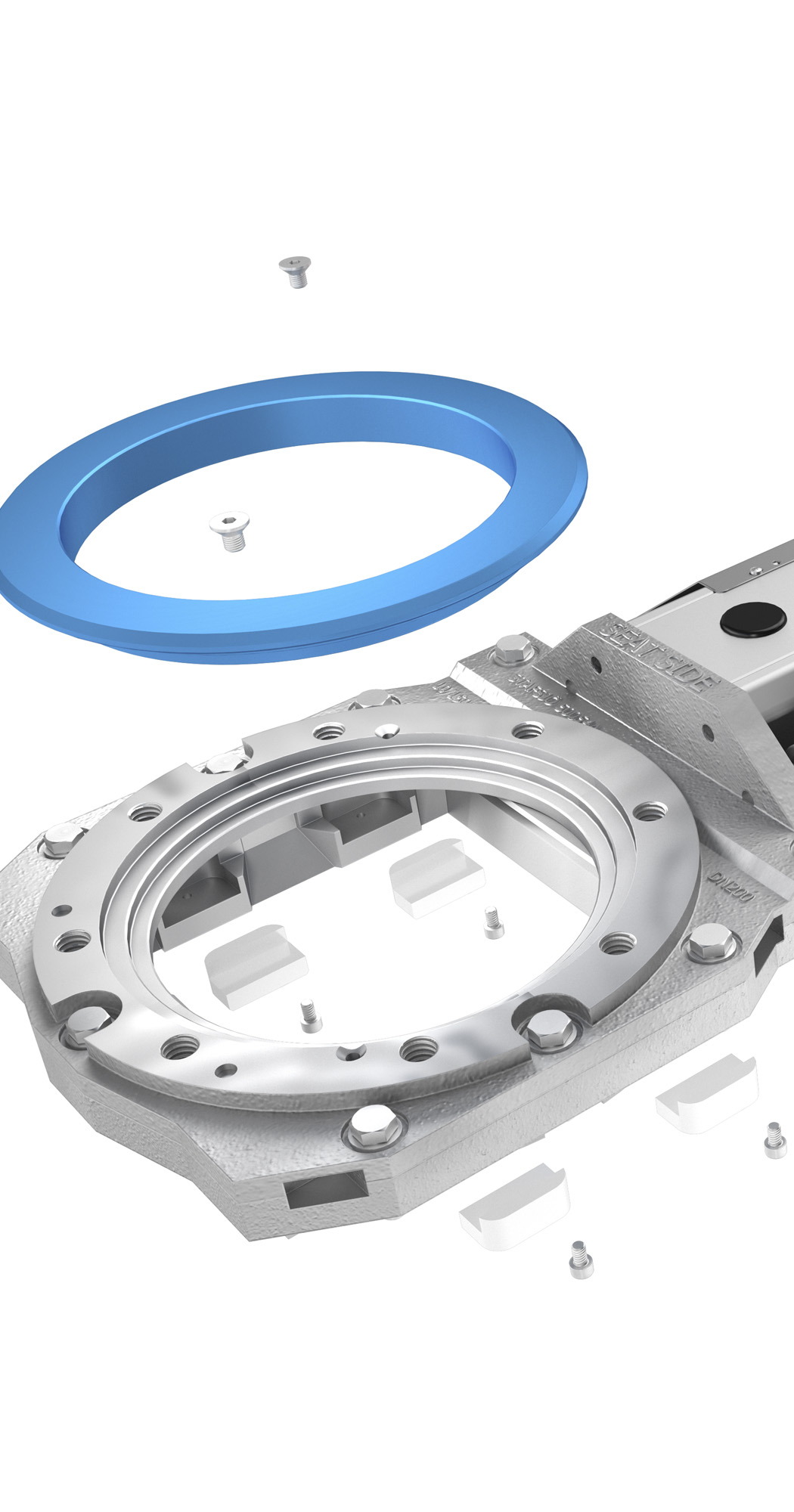

The RKO valve is modular designed and it can easily be customized in materials, with actuators and related automation accessories to different process conditions. It got a round inlet with an enlarged square outlet to avoid difficult solids will settle inside. An adaptor cone for the square outlet side can be supplied on request for weld or flange connection. Some sizes can also be supplied with standard flange pattern on the outlet side.

As standard RKO is available in a stainless steel and a nodular iron version. The top works is solid to perform during long periods of time in horizontal high cycling applications.

Download the product data sheet for additional technical information.

Specifications

Shut-off technique

Uni-directional

Valve seat material

Polyurethane

PTFE

Connection type

Fully lugged

Valve body material

Nodular iron

Stainless steel

Industries

Biomass

Chemical

Pulp and Paper

Product features

Performance shut-off on heavy coarse reject

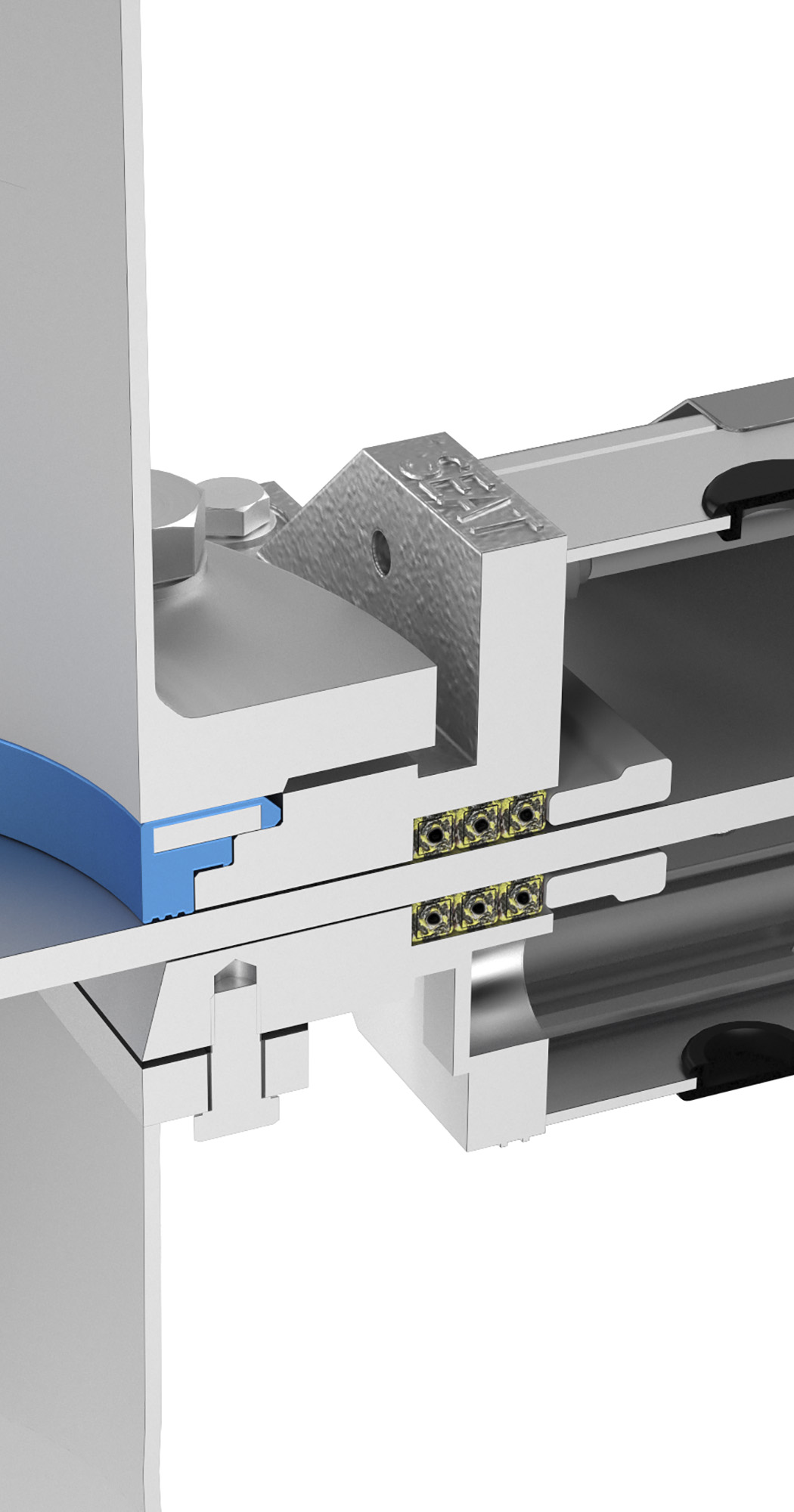

A first rate external sealing

Quick and easy maintenance

Downloads

- Title Format Size Restriction

-

Knife gate valve RKO

PDF 2 MB

- Title Format Size Restriction

-

Manual actuators

PDF 2 MB -

Double acting pneumatic cylinder SC

PDF 1 MB -

Hydraulic cylinder

PDF 2 MB -

Electric motor AUMA

PDF 91 KB -

Electric motor LINAK

PDF 1 MB -

Stafsjö standard accessories

PDF 4 MB

- Title Format Size Restriction

-

Durable valves in a tough environment

PDF 693 KB

- Title Format Size Restriction

-

Knife gate valve specification guide

PDF 5 MB

- Title Format Size Restriction

-

Installation and service instruction

PDF 4 MB -

Maintenance instruction for RKO and JTV

PDF 641 KB

- Title Format Size Restriction

-

3D STP PDF RKO DN100 DN600 SC

ZIP 65 MB